Personal

Science topics

Semicrystallin polymers deformation

Prothesis

of anterior

cruciate ligament

Mantle rheology

Educational Resources

Deformation Mechanisms in

Semicrysalline Polymers

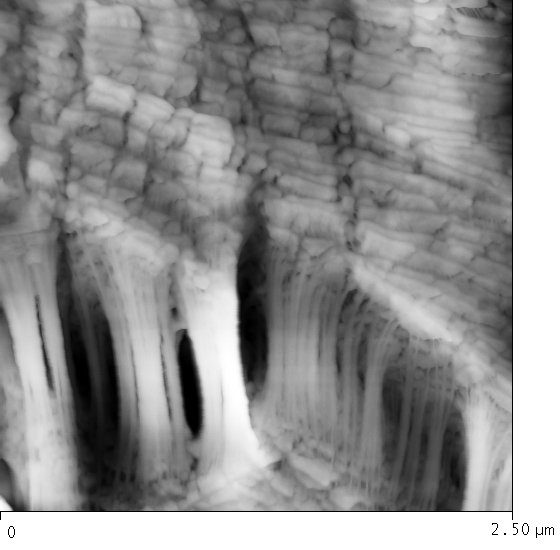

The aim of this work is to study the nano-scale deformation mechanisms within the spherulitic structure of semi-crystalline polymers. The deformation mechanisms are imaged by atomic force microscopy. The originality of this work is the use of a home-made tensile drawing stage under the AFM head in order to perform in situ tensile tests (Figure 1).

Figure 1 in situ tensile testing machine

The

observations performed on several semi-crystalline polymers such as

polyamide 6 (PA6), polybutene (PB) and polycaprolactone (PCL). Theses

observations revealed fragmentation of

crystalline lamellae (Figure 2) and micro-crazing (Figuree 3). These

mechanisms appear from

the end of elastic stage, and induce permanent deformation and

degradation of mechanical properties.

Figure 2 AFM height image

of

fragmentation in PB

|

Figure 3 AFM height image of micro-crazing in PB

|

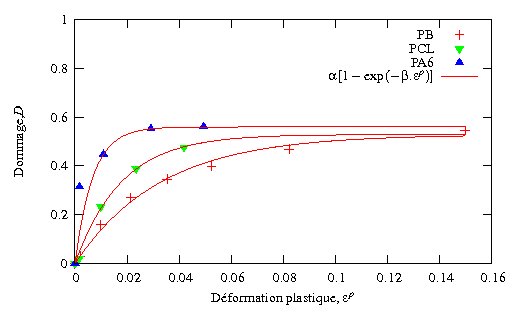

These experimental observations

enable assuming that there is a

coupling between plasticity and damage. The viscous contribution is

first identified, then subtracted from the data of cyclic tensile tests

in order to assess the damage and the plastic deformation. The damage

evolution follows the same law for the various materials in spite of

their large structural differences (lamellar thickness, spherulite

diameter, glass transition temperature, ...) (Figure 5).

Figure 4 Law coupling

damage and cumulated plastic strain

|

Figure 5 Rheological model |

The mechanical behavior

modeling based on the concept that the

semi-crystalline polymers consist of a macromolecular network flanged

by the crystalline structure. The behavior law has been developed with

this concept including the damage law previously identified (Figure 5).

This law

has been implemented in a finite element program, ZéBuLon. Good fits of

the

experimental monotonic and cyclic tensile tests have been obtained

together with fairly good predictions of the relaxation behavior of

three studied materials (Figure 6).

Figure 6 Model versus

experiment (Polybutčne case)